Source: Toolmaker

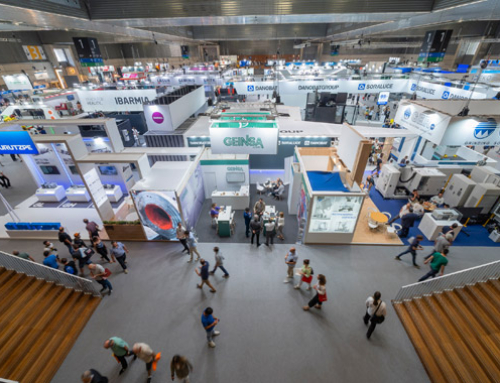

Haas Automation will undoubtedly be the centre of attention at the forthcoming BIEMH 2016 exhibition, taking place in Bilbao, Spain on May 30th – June 4th. The US-based company and its Spanish Haas Factory Outlet (HFO), part of HITEC Máquinas CNC SL, will use the high-profile trade show to exhibit a number of high-performance, competitively priced CNC machine tools, various high-productivity Haas CNC rotary tables, as well as the Haas VF-16 F1 show-car. The Haas F1 Team will have raced for the first time at the Circuit de Barcelona-Catalunya, just two weeks previously, on May 15th.

Among the new Haas CNC machine tools on display will be the Haas UMC-750SS, a Super-Speed version of the company’s popular universal five-axis machining centre. The UMC-750SS is a five-axis, 40-taper model equipped with a 15,000 rpm inline direct-drive spindle, a high speed 40+1 tool side-mount tool changer, and Haas Automation’s powerful, high speed machining software. It offers travels of 762 x 508 x 508 mm, 30.5 m/min rapids and an integrated high speed, dual-axis trunnion table.

The Haas ST-20SSY high-speed, CNC Y-axis lathe will be fitted with the all-new Haas bar feeder designed to provide simple, reliable, affordable, unmanned machining. The Haas Bar Feeder is designed and built for use with the range of Haas turning centres, from the Haas ST-10 through to the ST-35 CNC, and connects directly to the Haas CNC. Rollaway design provides easy access to the rear of the lathe spindle for quick liner adapter and liner changes.

Also at BIEMH, Hall 2 Stand B46, will be the newly developed Haas DM-1 high-speed 40-taper drill/mill centre. The inline direct-drive spindle turns to 15,000 rpm, and allows high-speed rigid tapping. Furthermore, the spindle is coupled directly to the motor to reduce heat, increase power transmission, and provide excellent surface finishes. The DM-1, which offers a 508 x 406 x 394 mm work cube, provides cutting feed rates to 30.5 m/min for high speed milling, while the machine’s 18+1 side-mount tool changer swaps tools quickly to reduce non-cutting time.

“We joined forces with HITEC Máquinas CNC SL around four years ago,” says Mr Jens Thing, managing director of Haas Automation Europe. “In that short time, the company and its people have invested significant capital and enormous energy in Spain, to create one of the best HFOs in the world. We expect BIEMH to be another great opportunity for the company to strengthen and grow its market share.”

In late February, the HFO in Barcelona, Spain, received a rather different request…from the Haas F1 Team, which, at the time, was testing its new, VF-16 F1 car at the local Circuit de Barcelona-Catalunya, ahead of the start of the 2016 Formula One world championship.

Andreas Le Noir is joint owner of HITEC Máquinas CNC SL: ““It was a great pleasure for us to help Haas F1 Team during testing in Barcelona by making and modifying some

critical parts for its car and its pit equipment. The challenge was to quickly source materials and tooling and deliver the parts ASAP,” he said. “We even delivered parts at 2 and 3 o’clock in the morning! F1 teams work 24 hours and, therefore, our applications engineers were challenged to manufacture parts in very quick time, working hard and long hours.”

He continued: “The HFO concept is designed to provide customers with sales and technical support as if they were dealing directly with Haas, but with local and personal service. This was a great example of how closely we work with Haas, and how Haas also supports us to provide the very best service and support possible.”

Source: Toolmaker

Leave A Comment